Global Supply Chain Shortages: The never ending loop of Supply Chain disruptions and the way forward

Manufacturing | December 09, 2021 | By

Supply Chain Disruption

The sudden rise in demand has led to chaos for manufacturers and distributors of goods who cannot supply as much as they did at pre-pandemic levels. To add to the woes, the geopolitical concerns and politico-economic issues that have been exacerbated for other reasons have affected the transition from pandemic to pre-pandemic levels, leading to global supply chain disruptions.

The trade war between the U.S and China has affected production on a global scale. The U.S.A is also facing truck driver shortages, as is Germany, with the former experiencing a backlog at its ports. In the UK, BREXIT caused a shortage of truck drivers. In the Indian subcontinent, there is a surge in the backorders especially for automobiles with a waiting time upwards of three months and in worst cases, it is more than half a year.

The impact on the product life cycle

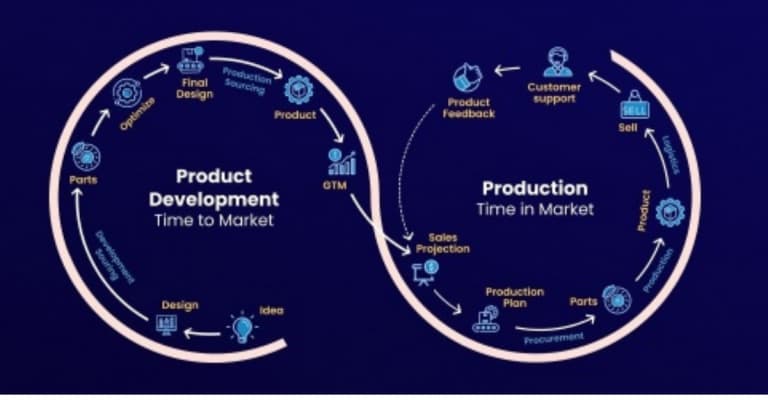

The impact of the issues is felt both in the first (New product development sourcing) and second (Products already in the market) phases of the product life cycle or as we folks at Zumen call it the S-curve(refer to the image below).

Supply Chain Disruptions Examples

When the chips are down: The global chip shortage

Electronic chips are small components inside several new-age gadgets and automobiles that work tirelessly to power our everyday lives. But, there is a problem, there are not enough of these components to manufacture products already on the market. Imagine the situation for the ones that are yet to enter.

In the global automotive industry, the ongoing problem is likely to cost around $110 billion in lost revenue, according to AlixPartners. The consulting firm has indicated that the industry could shift between 1.5 million and 5 million fewer units this year than previously planned. Also, with unrelenting demand for electronic gadgets, Samsung had delayed the launch of its new Galaxy Note mobile phone model. Sony and Microsoft also saw reduced supply in their next-generation consoles.

The problem is there to stay, and also experts say there will be a rise in prices for chips that will be borne by the consumers.

Glasses missing in masses:

There is usually a high-spirited demand for liquors in the U.S and the world during Christmas and the new year. But that is not the problem. The problem is there is a paucity of bottles to pour!!!

The reason? Looming labor shortages, rise in transportation(skyrocketed container costs), and energy costs. This is because of the already mentioned trade war between China and the U.S.A that imports almost 70% percent of the bottles from China which necessitated the shift to look for other sources which are not easy to pull off. Also, there is no substitute for glass bottles in the luxury liquor space, else they don’t look cool.

The surge in demand has forced larger companies to order years in advance and this, in turn, widened the gap between demand and supply.

And a personal pro tip: If you run out of glasses, wine out of gravy boats isn’t a bad option.

The disruptions and shortages are here to stay

With the global economy continuing to gather steam, the question is how it will be stymied by the supply chain disruptions cropping up at every nook and corner of the world. The emergence of new virus variants, border control and mobility restrictions, unavailability of global vaccine pass, and pent-up demand have joined hands hampering deliveries, increasing costs, and affecting the global GDP.

Also, the pandemic has highlighted how interconnected and destabilized the global supply chains are, with disruptions in one area creating a ripple effect on all parts of the chain. This has raised the topic of supply chain resilience to the boardrooms.

The disruptions due to supply chain shortages (examples like semiconductor chips, plastics, glass bottles, and the likes) were up by 638% in the first half of 2021 and are likely to increase considering the rise in cases globally and the advent of the new Omicron variant. Unfortunately, the situation “will get worse before they get better,” say experts like Tim Uy of Moody’s Analytics as this year is on track for record-breaking global supply chain disruptions and shortages. In another study released by Resilin, a global leader in the supply chain risk-monitoring space, apart from direct, pandemic induced causes, human-caused supply chain disruptions are rising overall, and the uptick is due to gaps in processes and a lack of skilled labor.

The lesson to be learned and the way forward

Common causes for the issues mentioned are the overreliance on a single supplier for a large portion of the components and poor supply chain planning & tracking systems. Significant time and effort, are taken to understand the current statuses let alone reacting in real-time.

Organizations need to move from a single supplier and just-in-time model to multiple suppliers and just-in-case model, stockpiling to hedge against future shortages. But, this could lead to a bullwhip effect and may end in the overproduction of components, cost of inventory, and price increases for the customers.

Here is where manufacturers need to double down to leverage technology to gain insights into their supply chains so they can respond to sudden shifts in demand vs. supply. Instead of relying on traditional methods, manufacturers need to gain visibility and flexibility, which is the first step to digital transformation. For example, an end-to-end Source-to-Pay platform. When requisite data is available in pre-configured dashboards, organizations need not spend their resources gathering, observing, and deducing data to take action. One clear thing is that be it Covid-19, an act of terrorism, trade war, regulatory changes, climate changes, labor disputes, or sudden spikes in demand, organizations that deploy the right digital technologies will be ready to deal with even the unprecedented.