Supplier Selection Criteria: Costs No More the Only Factor

Business | July 15, 2022 | By

Supplier Selection Criteria:

Cost is no more the only major factor for supplier selection and evaluation. In any product manufacturing company, when the decision is to outsource certain parts of the Bill of Materials (BOM), the first step is to select the right supplier who will be suitable to manufacture the said component. And to ensure supply is secured over a period of time amidst supply chain disruptions such as material and labor shortages, longer lead times, and port shutdowns in certain parts of the world, procurement teams are expanding their network of suppliers. While this move helps manufacturing companies ensure supply even during difficult times, it can also bring in new risks. To mitigate the risks, companies need to look beyond cost when selecting and evaluating new suppliers, and this requires a complete understanding of the current procurement situation.

Evolution of Industrial Buying procurement situation classification

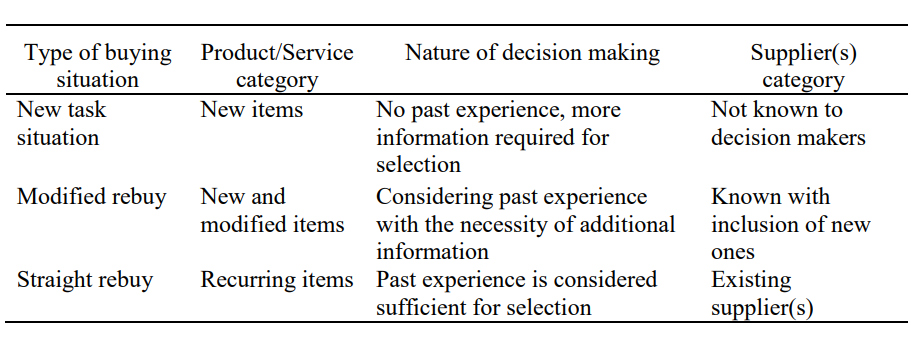

In the year 1967, Faris et al. distinguished three typical purchasing situations, as shown in Table 1.

Table 1: Classification of Purchasing Situations (Faris et al., 1967)

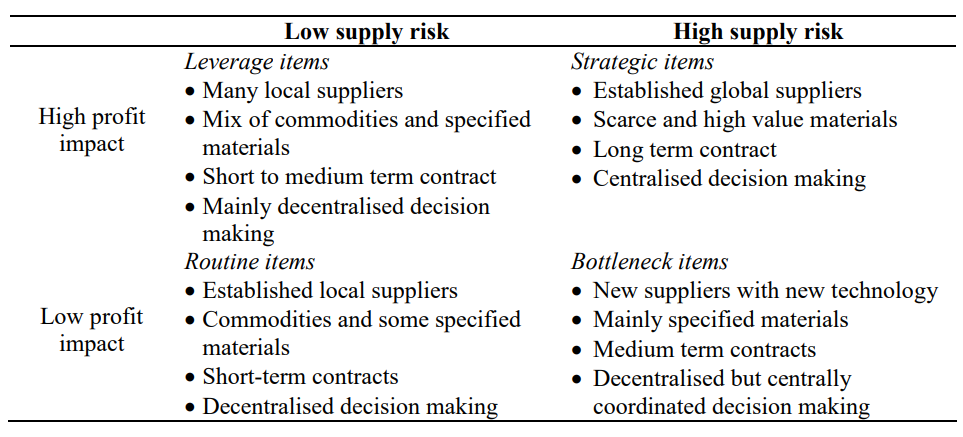

In 1983, Kraljic classified procurement activity into strategic, bottleneck, leverage, and routine purchases in terms of supply risk and profit impact. Kraljic’s portfolio took into account the supply risk and profit impact. These two variables influence decision-makers to determine the supply strategy needed for the company. The buying organization shall classify all its components in terms of profit impact and supply risk. This strategy will allow the buying organization to weigh its bargaining power against the suppliers.

In 1983, Kraljic classified procurement activity into strategic, bottleneck, leverage, and routine purchases in terms of supply risk and profit impact. Kraljic’s portfolio took into account the supply risk and profit impact. These two variables influence decision-makers to determine the supply strategy needed for the company. The buying organization shall classify all its components in terms of profit impact and supply risk. This strategy will allow the buying organization to weigh its bargaining power against the suppliers.

Table 2: Kraljic’s Portfolio Model

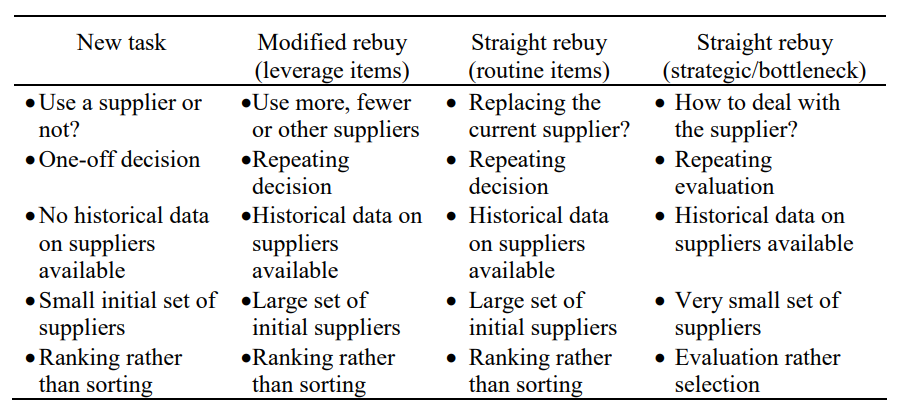

Later in 2001, De Boer et al. incorporated both classifications into a modified framework, as shown in Table 3. This offers buyers a manageable number of different supplier selection situations.

Table 3: Supplier Selection Criteria Framework (De Boer et al.)

Supplier Selection Criteria:

In general, when selecting suppliers, product cost has been the primary selection criteria. We have seen in the last two or three years that supplier selection based on the lowest bid value will do more harm than good. Here are a few criteria, other than cost, to consider when selecting new suppliers.

New Product Innovation:

When selecting suppliers for new product development, it is important to consider whether they will be able to meet the demands of developing a new product. The suppliers should be able to collaborate with the buyers and design team during the design iteration process. They should be able to visualize the product and provide inputs, for example, on the manufacturability of the part/component in large quantities in the long run. The collaboration will provide companies a greater competitive advantage and will help them bring the products with a faster time-to-market. In order to drive innovations, the suppliers should be willing to experiment, learn and adapt.

When selecting suppliers for new product development, it is important to consider whether they will be able to meet the demands of developing a new product. The suppliers should be able to collaborate with the buyers and design team during the design iteration process. They should be able to visualize the product and provide inputs, for example, on the manufacturability of the part/component in large quantities in the long run. The collaboration will provide companies a greater competitive advantage and will help them bring the products with a faster time-to-market. In order to drive innovations, the suppliers should be willing to experiment, learn and adapt.

Financial Strength:

Checking the financial health of the suppliers is a must, be it for new (before onboarding) or existing suppliers (periodic check). When disruptions happen, there may be inflation and thereby an increase in raw material prices. As input costs keep increasing, it automatically reduces the working capital. What this means for suppliers is more stress financially. But, the suppliers should have the wherewithal to wade through the rough tides. Else, it will have a significant impact on their service and/or quality.

Checking the financial health of the suppliers is a must, be it for new (before onboarding) or existing suppliers (periodic check). When disruptions happen, there may be inflation and thereby an increase in raw material prices. As input costs keep increasing, it automatically reduces the working capital. What this means for suppliers is more stress financially. But, the suppliers should have the wherewithal to wade through the rough tides. Else, it will have a significant impact on their service and/or quality.

Diverse supplier base:

To ensure production does not halt, companies need a diverse supply base to mitigate supply shortages with alternate sources of supply. The same applies to the supplier base of suppliers. For example, in a product manufacturing company, if one of the tier-1 suppliers that supply critical components has only one single supply source for the raw material, then it becomes a problem. If that particular supplier gets affected by supply disruptions, it will impact the tier-1 supplier, who will not be able to provide the critical component on time. What happens here is that the procurement folks immediately need to scout another supplier. And the selected supplier should match the requisite criteria. The delay here will affect the go-to-market and we know by now what happens if there are delayed product launches.

To ensure production does not halt, companies need a diverse supply base to mitigate supply shortages with alternate sources of supply. The same applies to the supplier base of suppliers. For example, in a product manufacturing company, if one of the tier-1 suppliers that supply critical components has only one single supply source for the raw material, then it becomes a problem. If that particular supplier gets affected by supply disruptions, it will impact the tier-1 supplier, who will not be able to provide the critical component on time. What happens here is that the procurement folks immediately need to scout another supplier. And the selected supplier should match the requisite criteria. The delay here will affect the go-to-market and we know by now what happens if there are delayed product launches.

Also, it is best to look for new suppliers with a multi-country footprint to guard against any local supply disruptions. Companies that were heavily dependent on supplies from China and Vietnam faced heavy losses because of the pandemic lockdowns in those regions.

Faster delivery, multiple inventories, and minimal risk are some of the advantages of working with suppliers who have a multi-country footprint.

Procurement Technology Adoption:

Just like the buyer organization, supplier organizations also fall under the product manufacturing category. To ensure complete visibility, elimination of non-value-added activities, proactive approach to direct material procurement, and much more, (Please refer to our blogs on direct material procurement lifecycle to know more.), organizations need the right direct procurement technology, and partners, to manage supply chains. This gives both the buyer and supplier organization a competitive edge. Zumen is a Source-to-Contract software that is built for the rigor, complexity, and repeatability of direct material procurement. Need the right procurement technology partner? Look no further!.

ESG and Ethical Procurement Practices:

ESG and Ethical Procurement Practices:

Environmental, social, and governance guidelines, enable a business to adhere to socially acceptable practices, be environmentally friendly, and be ethically governed. Being aware of the varying factors involved in procuring and sourcing products and raw materials is important for being considered a socially responsible company. The three categories in ESG compliance cover a variety of factors.

Under the umbrella of environmental guidelines are issues such as climate impact, greenhouse gas emissions, air and water pollution levels, water scarcity, and energy efficiency.

The health and safety of the workers, anti-corruption practice assurance, and a positive impact on the local community and employment are some of the factors that fall into the social category.

Governance ensures that companies avoid conflict of interest. It also pertains to executive compensation, alignment of interests, board independence and compensation, and other shareholder rights.

While ESG practices are a top priority, ethical business practices are equally important to safeguard a company’s reputation. Before onboarding a supplier, it is essential to ensure that the supplier is ethical and ESG-compliant.

Conclusion:

Procurement teams work with multiple factors before they even select a supplier. The factors mentioned above are only some of the key factors. Alongside selecting the supplier based on multiple criteria, procurement teams juggle between outdated procurement software, emails, and spreadsheets. To top it all, they have to ensure the product costs stay within the budget. It is time they are acknowledged and provided with the tools that allow them to concentrate on core-decision making such as finding the right supplier. We are here to help! Write to [email protected] or schedule a free demo.

ESG and Ethical Procurement Practices:

ESG and Ethical Procurement Practices: