(NPD) New Product Development Process : Early Engagement of Procurement in NPD

Business | June 01, 2022 | By

Your company sees an exciting opportunity in the market for a particular product. There is a huge gap in the market segment, and you feel that launching a new product will help you tap that part of the market.

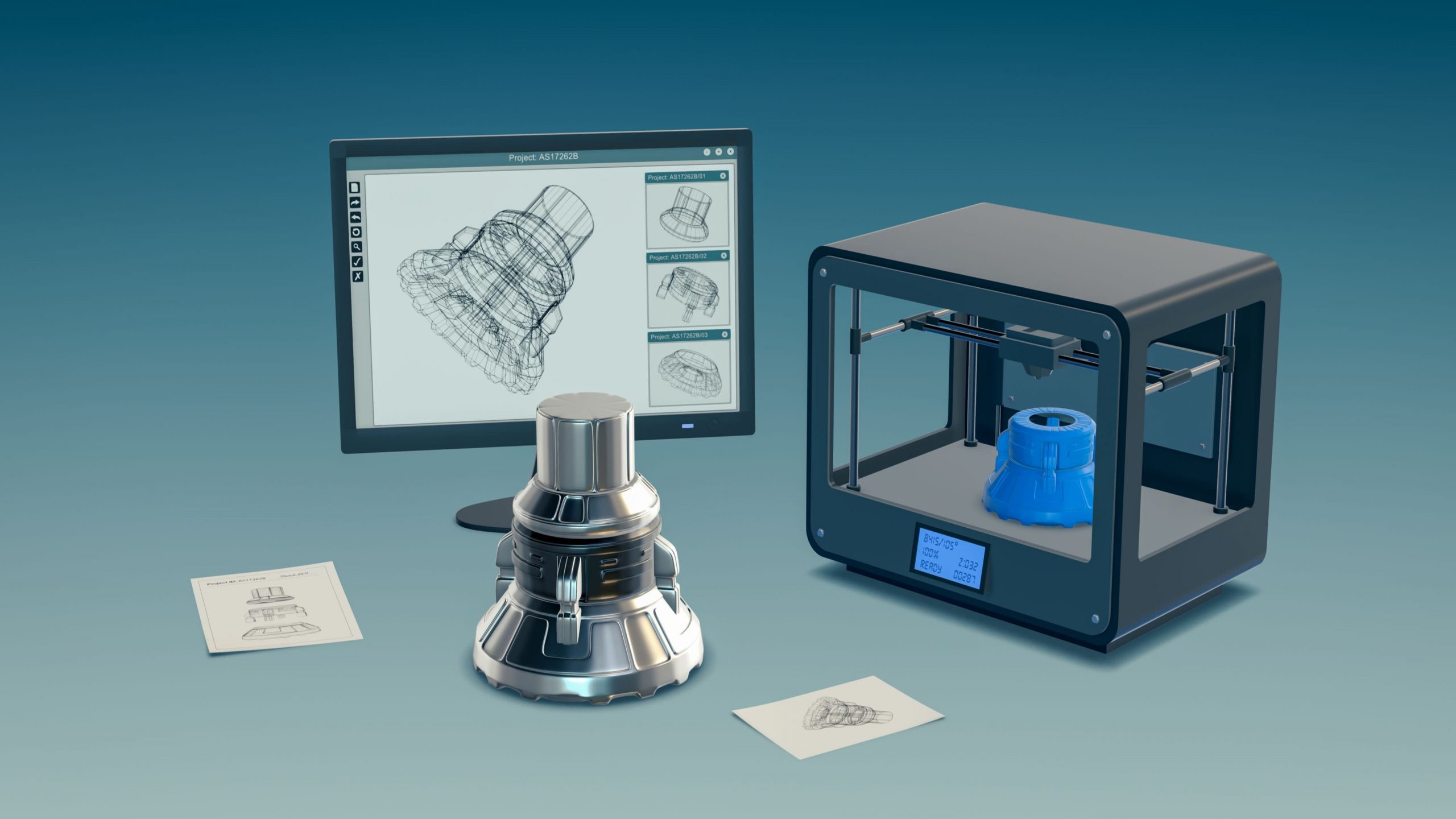

Now, there are two ways to approach this situation. You can launch a completely new product, starting with an idea, till Go-to-Market (GTM), or, if possible, upgrade the existing product with the required new features. This means that irrespective of the approach, you have to go through the New Product Development (NPD) cycle.

What is New Product Development (NPD)?

NPD is the process of developing and bringing new products to the market.

The 2nd edition of the Product Development and Management Association (PDMA) handbook defines New Product Development as, “A disciplined and defined set of tasks and steps that describe the normal means by which a company repetitively converts embryonic ideas into saleable products or services.” And, according to Wheelwright and Clark (1992), NPD is defined as effective activity organization and management, to bring products to market with low development costs and short development times.

In this blog, we will be discussing the NPD process in brief with two case studies and then see why it is essential to involve the procurement, early in the development process along with the benefits of such an undertaking.

The New Product Development Process:

Ideation & Design

The first and foremost step in any development process is starting with an idea. Product Engineering and Design teams with inputs from Sales and Marketing teams, and customers, convert ideas into product designs. The inputs are given based on the result arrived by doing the necessary research. This is also the phase where the objectives for the new product, the ‘what, ‘why’, and ‘how’ are decided.

The first and foremost step in any development process is starting with an idea. Product Engineering and Design teams with inputs from Sales and Marketing teams, and customers, convert ideas into product designs. The inputs are given based on the result arrived by doing the necessary research. This is also the phase where the objectives for the new product, the ‘what, ‘why’, and ‘how’ are decided.

Proto Build, Testing, and Optimizing

Once the design is ready for initial testing, it is shared with the procurement and sourcing teams. The members of this team study the design and select the suppliers who can supply the parts/components. After the parts reach the plant, the engineers use them to assemble the prototypes of the product and test them out. This process of building the prototype, testing, and optimizing the design goes on and on until the engineering teams are satisfied and gain confidence in the design. With every build, the teams record their observations on the design, supplied and in-house manufactured parts, and production aspects during every phase of the optimizing process. And they reach a point where they get closer to the final product that could be taken to the market.

Once the design is ready for initial testing, it is shared with the procurement and sourcing teams. The members of this team study the design and select the suppliers who can supply the parts/components. After the parts reach the plant, the engineers use them to assemble the prototypes of the product and test them out. This process of building the prototype, testing, and optimizing the design goes on and on until the engineering teams are satisfied and gain confidence in the design. With every build, the teams record their observations on the design, supplied and in-house manufactured parts, and production aspects during every phase of the optimizing process. And they reach a point where they get closer to the final product that could be taken to the market.

Production Sourcing

In general, in most companies, the procurement and sourcing teams are involved in the NPD process after the design is finalized. With the design or Bill of Materials (BOM) available, stakeholders, such as the members of the production, procurement, sourcing, engineering, and finance teams sit together and discuss the feasibility of manufacturing the parts inside the factory or acquiring the services of vendors – Make or Buy decision. If the decision is to procure from vendors, Request For Purchase (RFPs) are created by the respective departments and assigned to the buyers. After due diligence, the buyers reach out to various vendors to submit the quotations – Request for Quotations (RFQs). Once the quotations are submitted by the vendors, the buyers evaluate them and choose the right supplier for the right part. And, the suppliers are onboarded after the final contracts are drawn.

In general, in most companies, the procurement and sourcing teams are involved in the NPD process after the design is finalized. With the design or Bill of Materials (BOM) available, stakeholders, such as the members of the production, procurement, sourcing, engineering, and finance teams sit together and discuss the feasibility of manufacturing the parts inside the factory or acquiring the services of vendors – Make or Buy decision. If the decision is to procure from vendors, Request For Purchase (RFPs) are created by the respective departments and assigned to the buyers. After due diligence, the buyers reach out to various vendors to submit the quotations – Request for Quotations (RFQs). Once the quotations are submitted by the vendors, the buyers evaluate them and choose the right supplier for the right part. And, the suppliers are onboarded after the final contracts are drawn.

Go To Market (GTM)or Launching to Market

Once the suppliers are onboarded, and the in-house production is in full swing, it is time for ensuring the availability of all the components or parts of the BOM. After the components of the BOM are available, the product is ready for final assembly. Post final assembly, the in-house quality teams test the product and release only those products for dispatch that meet the quality requirements. The product is then brought to the market by the marketing team. The sales and marketing teams work in tandem and ensure the product is introduced to the market using the right product strategy. The target market, positioning strategy, advertising, distribution, pricing, branding, packaging, and budget levels are all decided. The product is launched and the life cycle of the product in the market starts here.

Case Study I: The Curious Case of a Medical Technology Company

In the NPD process above, the procurement and sourcing teams are included in the NPD process only after the design is finalized. One such case study is recorded in a Harvard Business Review (HBR) article.

A medical technology company (name not revealed) in the manufacturing of high precision medical equipment space was considered. It is a $100 million enterprise with huge success in its domain. The company had an impressive growth record and was no stranger to cutting-edge technology. It enjoyed an enviable reputation for delivering high-performance, dependable, and cost-effective products for hospitals and medical research facilities. The company’s new product, a machine that was to contain several monitoring functions and could perform several sophisticated data analyses, represented a potential technological breakthrough. This product could give the company a clear competitive advantage for at least three years. But the project did not begin well, at least not to the extent the company wanted.

See, the company had two design configurations. And, both of them were competing ones and were pitted against each other by their respective departments who proposed them. One was a key component, based on an entire concept in buffer circuit design. A strong favorite of the engineering and marketing departments. Who wouldn’t like a technologically advanced product? And such new inventions are golden tickets any marketing team would want. Yet, manufacturing urged a somewhat more conventional design. The team persisted till the end, yet, the management went in favor of the advanced design.

The result? A downward spiral of setbacks. The first setback was initial cost projections. It proved to be far too optimistic. The cost of the equipment needed for the in-house manufacturing was around $600,000, which was $150,000 higher than the initial estimate. And, the purchased components exceeded the budget by a whopping 38%. The next logical step any company would take is to pass on the increase in cost to the consumers. The Marketing team intervened and protested that boosting prices to recover costs would severely affect the market share of the product. So, they came to a compromise: minor design changes to reduce costs, increase prices and decrease profit margins (in the hope that the profit can be recovered during the life of the product).

The next setback occurred during the assembly of the pre-production model. Components from two important suppliers proved incompatible, although both the suppliers met the purchase specifications reasonably. This further delayed the launch of the product, as some design modifications had to be made. And also, additional expenses cropped up for reworking tools and dies.

Shipments finally began seven months after the planned launch. The orders faired up well during the next four months. But, the total number of the shipped units was only 52, and not 175 as per the budget. And, out of the 52, more than half were defective (as reported by customers) and only 5 were repaired in the field; 11 were returned to the plant for more rework, and the remaining 13 were yet to be inspected by the company personnel. Owing to such huge issues, the quality and marketing teams called for a halt in the shipments until all the issues were solved. The overall results were discouraging, to say the least. The company conducted an audit and the post-audit findings were as below:

- Managerial and technical personnel were on par with the competition, and production facilities were among the best in the industry.

- Problems encountered during the launch of new products in the past did not even come close to the threat posed by the current launch.

- Though the product represented a big leap in technology, it was not more than a logical extension of the company’s prior products. The only difference is that the latest product used more purchased components and relied largely on the electronic and output mechanisms, which was out of the scope of the company’s design and manufacturing capabilities.

And you know what the post-audit concluded? That the recent launch program was plagued with bad luck in addition to the poor internal coordination and recommended that a new system be developed for the future. Despite the verity or relevance of the audit findings, HBR authors concluded that the audit was faulty and unproductive. And we second that. Because the analysis failed to determine the cause of the failure; It was not bad luck or misfortune, but rather an outdated approach to new product development. The approach is about engineering teams designing products meeting the price and performance criteria set by sales and marketing, and the manufacturing team meeting delivery deadlines with the cost targets. Where does procurement fit in here? The team was only given the task of ensuring the timely availability of required supplies obtained at the most economic prices. The procurement function was considered a clerical task rather than a technical or managerial task.

Case Study II: The Story of Alpha manufacturing company

Let us take another case study by Richard Erikkson and Linus Ronnback. Alpha is a global supplier of mechanical products and components with a presence in more than 100 countries. The product range varies from standard products manufactured in large volumes to customer-specific ones manufactured in very small series. Alpha operates in a very mature and competitive environment which has become even more intense, much due to new competitors.

Alpha has a long history with a series of factories and acquisitions that have given it a global reach. The organizational structure consists of divisions which in turn are divided into different departments based on the group of customers they serve. The new product development efforts are mainly undertaken within the different areas which means a decentralized product development structure. But, there is also a central research center to support the different development teams. The purchasing organization is divided into three different levels consisting of a central unit, several regional offices, and local purchasing offices located at each manufacturing site. The researchers conducted interviews with the members of the organization and have published their findings here. Below is the summary of the issues relevant to NPD.

Problem with Supplier Selection

The search for new suppliers at Alpha was ad hoc. Web search engines were often used to find the suppliers. In some cases, lists with suppliers were used. But, these lists are prepared by local organizations and therefore covered only geographically close suppliers. These suppliers were then contacted directly by the product development team itself. What happened here was that, during the discussions, the suppliers influenced the specifications that were favorable for them. And after all the discussions were completed, the engineer contacted the buyer to settle the deal and also approve the suppliers if they were new to Alpha.

The search for new suppliers at Alpha was ad hoc. Web search engines were often used to find the suppliers. In some cases, lists with suppliers were used. But, these lists are prepared by local organizations and therefore covered only geographically close suppliers. These suppliers were then contacted directly by the product development team itself. What happened here was that, during the discussions, the suppliers influenced the specifications that were favorable for them. And after all the discussions were completed, the engineer contacted the buyer to settle the deal and also approve the suppliers if they were new to Alpha.

The problem here is that such practices give no purchasing power to Alpha. The engineer may have an idea of which supplier to use, but unfortunately, this supplier will not be capable enough to support Alpha, aligning with the company’s objectives. And now, without any prior notice, the buyers need to find new and more appropriate suppliers despite a short time frame and very detailed specifications.

From both product development and purchasing, the inherent conflict between their functional objectives is singled out as the main cause for this. Product development on one hand has objectives focused on product functionality and performance. Therefore they want a supplier with the best possible technical competence and knowledge that can help them meet these criteria. On the other hand, purchasing finds production capacity and cost as more important aspects. One solution was to use standard parts/components, but product development then argued that the product output will not be the way they want it to be. A standout from the current ones in the market. unique enough.

Ineffective Communication & Data Sharing

The other problem is that the early communication during the initial phase of the NPD process between the procurement and the engineering teams is not optimal. One of the reasons is that, earlier, Alpha used to manufacture most of its components in-house and hence the requirement for a fully-fledged procurement function was not needed. But, as the procured components increased, the need for such a team arose. Even though the people at Alpha realized that cross-functional seamless communication is needed, there seemed to be no breakthrough.

The other problem is that the early communication during the initial phase of the NPD process between the procurement and the engineering teams is not optimal. One of the reasons is that, earlier, Alpha used to manufacture most of its components in-house and hence the requirement for a fully-fledged procurement function was not needed. But, as the procured components increased, the need for such a team arose. Even though the people at Alpha realized that cross-functional seamless communication is needed, there seemed to be no breakthrough.

Also, the product developer has difficulties identifying the buyer for different parts, since this information was not available. And there was also the difficulty in accessing information. Due to several acquisitions in the past, different systems were merged with additional interface systems. This made information flow between different functions and units within Alpha complicated since the access to most systems was restricted. The result was that the necessary information for product development from procurement and vice versa was hard to acquire. The systems did not support the cross-functional processes the way Alpha intended them to. Also, the engineers at Alpha were not aware of the other information required by the buyers and this resulted in incomplete specifications sent to the supplier.

Another issue was that there was a lack of accessible information from other functions. This was due to the lack of capability of the existing ERP systems that Alpha used and also, the strict line organizational structure that was followed. This is not an issue that could be solved by the procurement or the engineering teams, but something that needs to be included in the IT strategy of Alpha or any other manufacturing company. To create an integrated way of working, product development teams need to have access to the relevant information at procurement and the buyers need to have access to the necessary information within product development.

A New Role for Procurement Early in the NPD Process

The NPD approach in both the case studies may well suit the environment of the past. With rapid increase in technological changes, the expected frequency of new product launches has correspondingly increased, and also the time available for companies for ROI is shrinking putting additional strains on the product development teams. Technological advancements have also blurred the line of distinctions among categories of products. Take for example the semiconductor industry, almost any product that comes to the market is fitted with an IC chip. These developments make the above approaches in the NPD process untenable.

Also, the accelerated change in the social, political, and economic variables forces organizations to monitor their environments constantly. Procurement’s strategic involvement helps organizations monitor as the environment affects future procurement requirements. This calls for the buyers and suppliers to share information.

At the macro level, strategic involvement in procurement calls for the procurement manager or head of the procurement team to monitor the environment, forecast the changes, and share relevant information within and outside the organization(eg. suppliers). At a micro level, strategic procurement involves studying the Bill of Materials (BOM) completely to identify the critical materials, evaluation of possible supply disruptions, and develop contingency plans for all the possible supply problems.

But, going forward, the viability, integrity, and eventually the success of the product design, development, and production can be ensured only if procurement steps in early in the development process. Procurement teams are accustomed to working with manufacturing in most organizations, but now they will also be working with product and design engineers as well.

There are six ways, the involvement of procurement impacts the New Product Development Process:

- In the ideation phase, procurement can help the development teams with information such as the supplier’s new components that their suppliers have developed for other organizations. And this knowledge may enable identifying marketing and engineering the opportunities available and also understanding the capability of that supplier.

- In the next phase, when the objectives for the program are about to be set, procurement can help establish cost, performance, timeliness, quality, and reliability objectives. Also, they can inform other departments, about the capabilities of various suppliers – who can and cannot meet the program requirements.

- Sometimes there may be a time when the initial set of ideas may not be enough. So the development teams go for alternate conceptual solutions. When procurement is involved early in the development process, they can offer input about the factors that could impact the delivery of materials, components, and sub assemblies.

- Also, during the several design reviews, the involvement of procurement is of much importance. They can help in deciding the use of standard items related to the product available with the suppliers. And this has to be done with careful trade-off analyses between the performance, reliability, and cost advantages.

- Furthermore, once the design is finalized and shared with the procurement for sourcing, they can challenge any uneconomical requirements that are not in the company’s best interests. Procurement can also encourage suppliers to take part in the development process and also consider their suggestions on technical and financial aspects.

- Finally, there are times when there are changes made to the product. This would impact the cost of the product and also have significant delivery implications. Procurement, together with relevant stakeholders such as the product and design engineering teams, sales, and marketing can help evaluate such issues and provide feasible solutions to the organization.

The Future is Now:

We live in competitive times with constant supply-chain disruptions. However, businesses have to run to sustain themselves in the market. And firms that are slow in launching new products will slowly fade away into oblivion. Hence, it is necessary for organizations to always stay on top of the competition by bringing new products as quickly as possible. And this calls for early involvement of procurement and suppliers in the new product development process. According to a Gartner survey, 40% of respondents ranked early involvement of procurement in NPD as a top-five value lever. Companies cannot succeed with old ways of doing things. What they need is a tool that is built for the New Product Development process. And the search ends with Zumen.

When involving cross-functional teams, it is important to have a digital platform that is built for New Product Development. Zumen is one such platform that caters to the NPD process. The benefits of such active participation procurement coupled with comprehensive software are aplenty. When all the relevant capabilities and expertise required are brought together in a single platform, it is possible to move away from siloed working, and make informed and effective decisions that are proactive rather than reactive.

Also, a platform like Zumen facilitates secured data sharing within the Zumen environment itself. Buyers can share the drawings to suppliers within the Zumen platform in any format, be it 3D, PDF, Jpeg, etc.

There is a need for structured communication between departments when an organization is involved in the NPD process. But, a major hindrance is the availability of a single source of communication between multiple departments and sometimes even multiple businesses based on the width and depth of the organization. And the limited capability of an ERP should not hinder coordination within multiple teams and even businesses for that matter.

With Zumen, the stakeholders are abreast of what is happening in every other department involved in the NPD process. Any small change, and all the relevant stakeholders are alerted immediately. And, here’s more, tracking the status of the program development is now easier. The individual and a summarized status of all the programs that an organization is working on can be viewed program-wise and build-wise using a live dashboard at any given moment. Also, all the communications in the context of the part are visible anytime so that there are no misses on any important communication and thereby, the deadlines.

Success of NPD projects is at the heart of a company’s growth, and at the heart of NPD, there must be room for what procurement has to say – and do.