What is a Purchase Requisition?

Business | September 11, 2022 | By

Manufacturing companies require multiple items daily, from raw materials, semi and fully-finished goods, to office supplies and services. And to purchase these goods, companies need to go through a systematic process that helps them manage these expenses effectively. And a purchase requisition or request for purchase (RFP) is the first step in the process.

A purchase requisition is an internal document that indicates the need for procuring goods or services. An employee fills in the necessary details in the purchase requisition form and sends it for approval. Based on the organization’s approval workflow, approvers review the purchase requisition document and either approve or reject it. The next step after approval is assigning the buyer. The buyers then start the sourcing process and release the purchase order (PO) to the selected suppliers.

How does a Purchase Requisition work?

Organizations have different processes to manage their purchase requisition workflows. But, the general outline will be the same across organizations and industries. And since we cater to discrete manufacturing companies, we’ll keep this discussion within that scope.

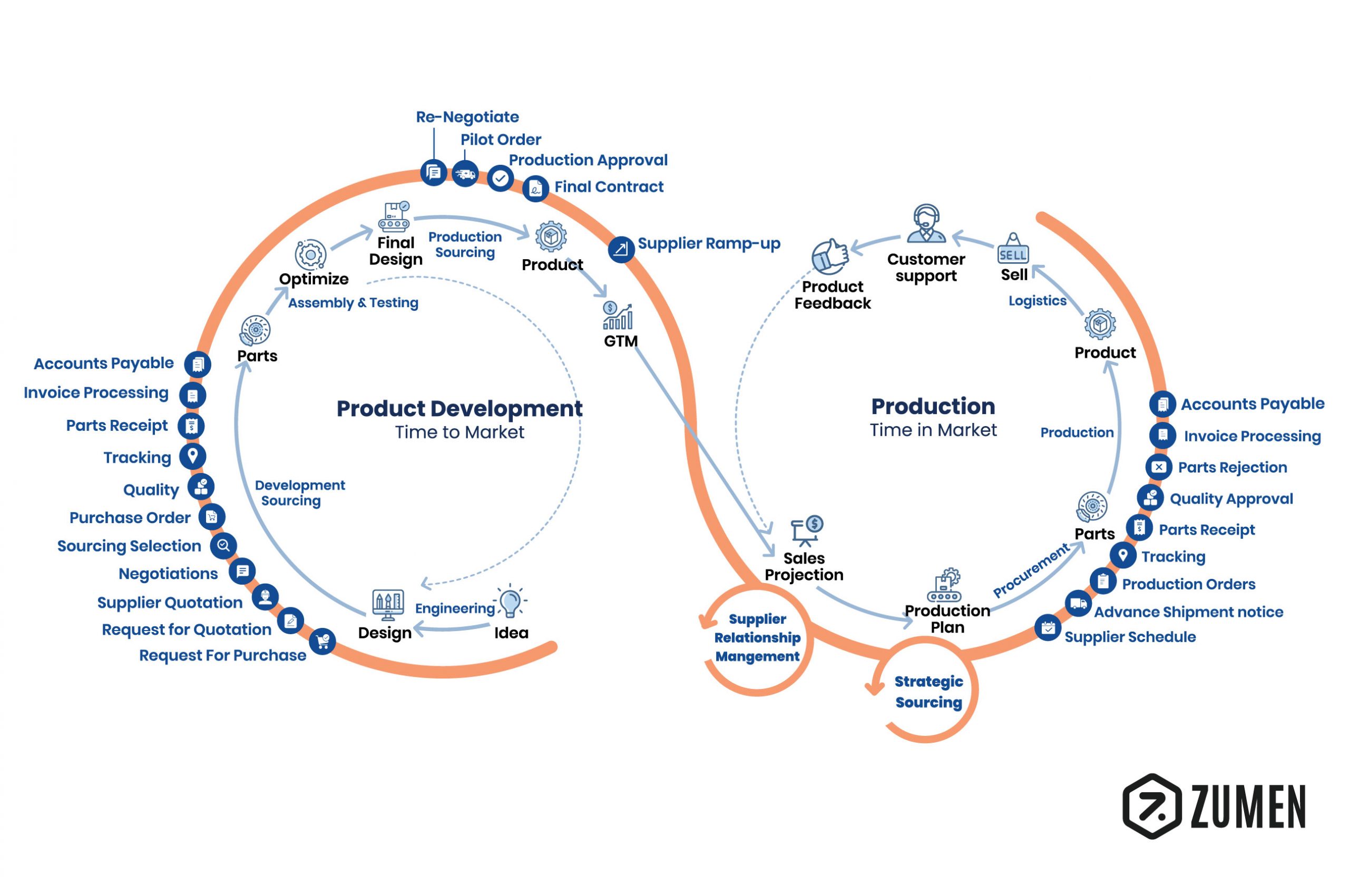

The inverted S-curve image below depicts the complete procurement and part lifecycle in direct material procurement, which is the process of procuring raw materials and components that go directly into the manufacturing of the end product. To learn more about the direct material procurement lifecycle, read our blogs here:

Direct Material Procurement Life Cycle Guide – Part 1

Direct Material Procurement Life Cycle Guide – Part 2

Now, let’s understand the various scenarios where purchase requisition is involved.

Scenario – 1

During new product development, which is the left half of the inverted S-curve, there will be multiple times and phases where purchase requisitions come into the picture, for example, during the proto, pilot, and production phases. Based on the make or buy decision the manufacturer takes, the concerned teams will send the requests for purchase (RFPs) for either the raw materials or the finished components. And the rest of the process is the same as mentioned above. The same process is followed for every component in the bill of material.

Scenario – 2

After a product is launched in the market, the first step in manufacturing a new batch is to prepare a Sales and Operation Plan (S&OP). The S&OP is the summation of forecast data shared by the sales and marketing teams, and the order booking details. Once the procurement team receives this plan, they prepare a materials requirement plan (MRP) by considering the demand against the open stock, materials in transit, and commitment from suppliers. This will give the list and volume of materials required. Generally, in most manufacturing companies, ERPs will do the back work and show only the materials required and their quantities. The purchase requisition will be automatically sent to the respective stakeholders for review and approval,

Who are the Stakeholders?

Given the importance of the purchase requisition, accurate and complete information should be captured to save time and resources across the process. Before moving on, let us see the stakeholders in the purchase requisition process.

Requestor

This person may be someone who belongs to any department in the organization, for example, an engineer from the engineering team requesting parts for the proto build during the new product development phase. While in other organizations, there will be separate teams who consolidate and handle all the purchase requisitions. This usually happens in the production phase.

Approver

An approver completes the RFP process once he/she approves the RFP. Based on the company workflow, there will be a single or multiple approvers. Sometimes, there will be no approvers at all.

Assigned Buyer

An RFP, approved or not, depending on the organization’s workflow, is then assigned to a team member, called the buyer, from the procurement team. Based on the material required, RFPs are assigned to buyers who are experts in procuring the specific commodity.

Other stakeholders

Apart from the above trifecta, and in context with the RFP or purchase requisition process, value analysts and other department heads are also apprised of the RFPs initiated. When a purchase requisition is approved, value analysts will start their work immediately after the RFPs are shared.

What does a Purchase Requisition Contain?

Now let us look into the details needed in the purchase requisition form.

-

-

- Program or project code and description

- Raw material, part, or item number

- Part description, quantity, commodity, and price

- Part maturity type (For example, pilot, proto, or production)

- Part revision details

- Potential supplier details

- Reason for purchase

- Target delivery date

- Number of shipments and shipment quantity

- Name and department of the requestor

- The date and time of the purchase requisition

- Delivery address

-

To summarize, a purchase requisition streamlines the procurement process, reduces the scope for mismanaged and fraudulent procurement practices, and provides better cost control. While purchase requisitions are highly beneficial, not all manufacturing companies realize the full benefits of the RFP document. Why? Because most organizations use ERP to raise RFPs and RFQs. And most organizations share the RFQs with suppliers by email or through a separate supplier portal and this breaks the process.

If you’d like your tool to carry the RFP details including the drawing file all the way to PO release, Zumen can do that and much more to support you in every step of the direct material procurement process. Detailed quotation comparison, PPAP, quality rejections, supplier performance dashboard, to mention a few. Sounds interesting? To learn more, write to us at [email protected] or schedule a free demo.