Direct Material Procurement Life Cycle Guide - Part 1

Direct Material Procurement | May 25, 2022 | By

The objective of this guide is to explain the Direct Material Procurement Lifecycle — details, exceptions, and complexities — in the context of product manufacturing industries. This would include companies in such industry sectors but not exclusive to Automotive, Auto-Ancillary, Industrial & Manufacturing Equipment, Recreational Products like boats and ATVs, Aerospace and Space Equipment, cellular and 5G infrastructure, Robotics, Industrial Automation, medical devices, agricultural, construction, and forestry machinery. We have observed that industries manufacturing pharmaceutical, food, and healthcare products also use similar processes but the key difference between the equipment industry and the latter would be that one falls in the discrete manufacturing space and the other falls in the process manufacturing space. We also believe this guide will serve as a reference manual for startups and growing companies in the manufacturing of discrete products to understand the global direct material sourcing and procurement processes and implement the right process for their companies; it will also help such companies select the right tool to manage their procurement process. For this reason, this guide will also serve as a good reference in the technology procurement process.

The content in this guide is presented in two parts:

Part 1 of the book provides an introduction to the direct material procurement lifecycle and the first phase of the life cycle that aligns with new product development and is referred to as ‘Source-to-Contract’.

Part 2 of the book discusses the second phase of the lifecycle that aligns with the production phase of the product and is referred to as ‘Procure-to-Pay’.

1. Introduction

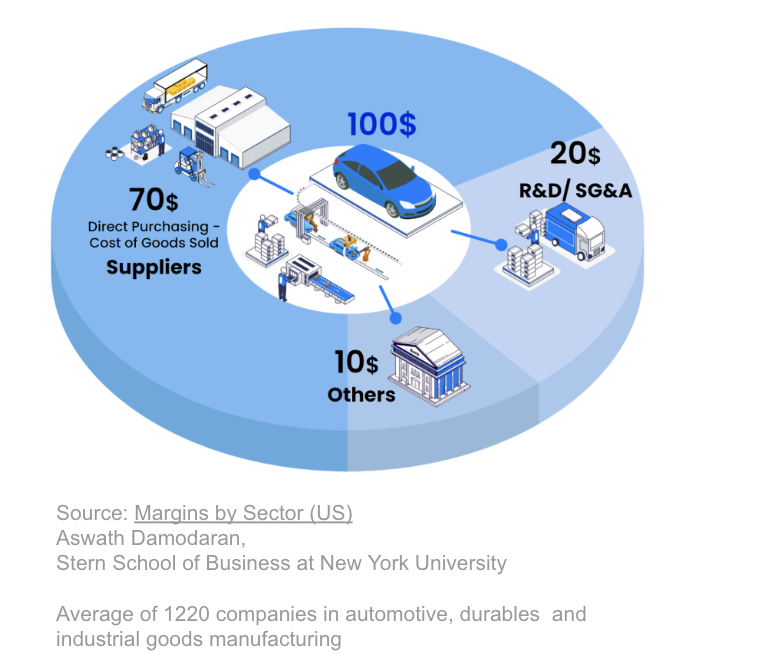

In manufacturing companies, particularly in Product Manufacturing  Companies, Direct

Companies, Direct

Material is a significant spend for the company as it accounts for 65-80% of the Cost of Goods Sold (COGS). Moreover, sourcing & procurement of Direct Material is a highly complex and extensive process that requires various stakeholders across the company/enterprise to gather data, make decisions, track progress, and coordinate delivery throughout the process. The depth, repeatability, rigor, competence and management strategy, and support of this process directly translate to the success of the product and the enterprise in the market. While it is easy for most people to relate to, understand, and help improve Business Spend Management, it is nearly impossible for anyone outside the manufacturing world, particularly product manufacturing companies, to understand the process, tools, and decision making involved in the Direct Material Procurement.

These days, the industries outside of manufacturing have realized the significant difference between the Direct Material or Direct Spend that directly transforms the unit product cost and impacts the product margin and the overall profitability of an enterprise and the Indirect Spend or Cost of Running a Business that denotes the efficiency of running an enterprise (Indirect Procurement & Spend Management).

While Direct Material Procurement is considered a product manufacturing company’s core competency and intellectual property, most new-age service and technology companies consider Indirect Procurement and business spend optimization a non-core activity.

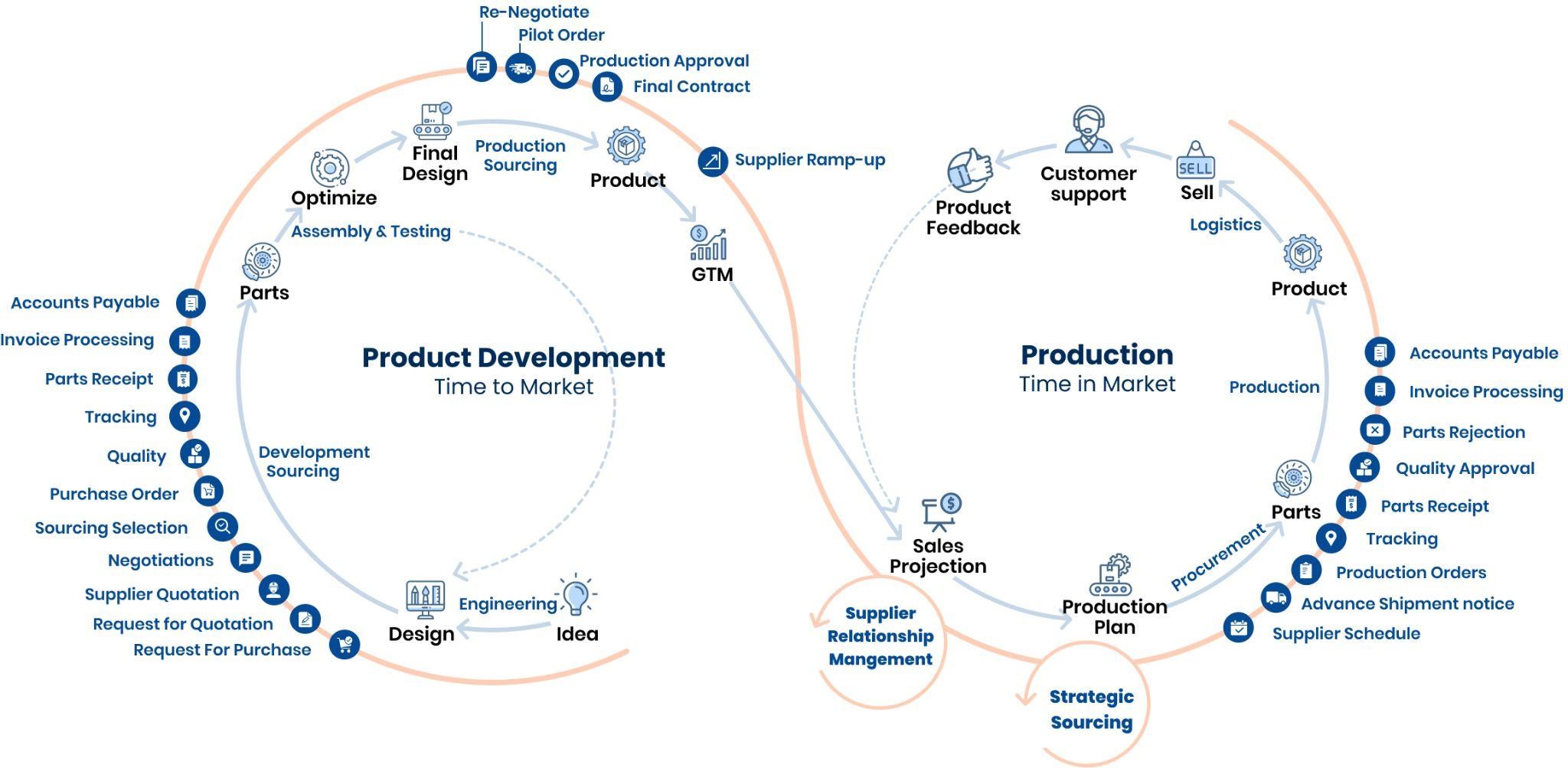

The Direct Material Procurement Lifecycle contains two phases:

1. Source-to-Contract: This phase of the Direct Material Procurement Lifecycle aligning with a New Product Development is typically classified in the procurement technology landscape as Direct Material Source-to-Contract. As the term implies, the primary output of this phase is the conclusion of the Product Development and the setting up of the suppliers for the production of the product as long as it is live in the market. For large and complex products, this phase lasts between 1 year to as long as 5 years. Success in this phase and the synergy between Product Engineering & Development and Direct Material Sourcing & Procurement determines the Time-to-Market of the product.

2. Procure-to-Pay: This phase of the Direct Material Procurement Lifecycle aligning with the useful life of a product is termed Direct Material Procure-to-Pay. During this phase, the product is already in the market and the objective of the procurement process in this phase is to ensure the items/ parts that make up the product are planned properly, tracked, and delivered on time to ensure products are made and the sales and revenue targets are met.

We will discuss the two phases of the procurement life cycle in detail in the following pages.

2. Source-To-Contract

Product Engineering and Design teams, with inputs from the Sales and Marketing teams, and customers, convert ideas into product Designs. These designs are then converted to products. To create the products, the companies also need help from several other companies, who are referred to as partners, vendors, or suppliers, in converting specific smaller concepts into components that can come together to make the whole product. While engineering teams are experts in developing designs for the products and components that make up the products, enterprises usually need another set of experts who specialize in identifying the right suppliers for these components from across the world. These are the sourcing & procurement professionals who specialize in finding the right materials and the right partners to make these components (This process is elaborated in section 2.1: Direct Material Sourcing).

During the Ideation and Design phase, the companies bring small quantities of new designs that can be put together and tested. Once the product engineers have had a chance to see the components and test them out, they may decide to make changes to the designs. Changes to the designs may be done for several reasons including better functionality, better performance, better reliability, and more importantly, better costs. These changes may require the procurement teams to bring another set of parts (or components) for another round of testing. And in the making of a product, this cycle of changes and tests may happen a few times. This cycle of improvement and testing is called ‘Product Development’. Product Development is also called New Product Development (NPD) to emphasize the fact that the team is creating a new product.

In successful companies, the procurement teams work very closely with the product engineering teams to help them find the right parts for every step of this improvement process.

They also continue to monitor the cost and quality of parts during these steps. The collaboration between the product engineering team and the procurement team in this phase defines the success of the new product. The time it takes for the product to complete the cycles of improvement and finally be ready to be introduced into the market is referred to as ‘Time to Market’. So, the procurement teams along with the supply chain and logistics specialists, keep track of the components from the time the design has been made available to when the part is made by the supplier and finally received at the company for assembly and testing (This process is elaborated in section 2.2: Parts Tracking).

Prototype Build, Testing & Optimization

Just like the name indicates, the engineers use these parts to build early prototypes of the product and test them out. The process of development through multiple trials of the product is nothing new and seems quite a common-sense approach. However, one should keep in mind the complexity we are talking about in terms of the expectation from the product, the number of design engineers working on different parts of the product, the suppliers involved, and the manufacturing process and tools involved – getting these working together and still delivering the product at the right cost at right quality at the right time is critical for the success of the product and the company. Add to that what the customers expect from the product and the liability involved. There are also other aspects in terms of industry regulations. Due to these reasons, the process of prototype planning, building, testing, and tracking issues for quick iterations and tight project management evolved and matured between the 1980s and 2010s, with the automotive industry pioneering the evolution. Depending on the industry and the company, the prototype stages were called alpha, beta, and gamma builds. Sometimes they are called a concept, functional, development, and pre-production build. There are also builds to secure regulatory approvals before launching the product in the market. Usually, before the final production, they have phases of pre-production referred to as pilot builds and ramp-up builds. With every build, the team makes observations on design, suppliers, and manufacturing for improvements and with every next phase, they get closer to the final product that could be taken to the market. So the expectations on the parts from the suppliers also continuously increase.

As the engineering team gains confidence in the design, they enable the sourcing team to start finding the suppliers to make the parts or components for the life of the product. Having the right suppliers is critical for the success of the product after it is launched in the market. Whether the products are made of 100’s or 1000’s of parts, companies will not be able to initiate their Go-To-Market (GTM) actions before finding the right suppliers for all their parts. This part of the process at the end of the optimization of the design is called production sourcing (This process is elaborated in section 2.3: Production Sourcing).

2.1. Direct Material Sourcing

The communication with the sourcing & procurement team and the suppliers during the Time-to-Market require providing several pieces of information regarding the part design.

The designs are usually shared in multiple forms of drawings (zumen) and 3-dimensional computer models. Further, converting the designs into physical parts requires everyone involved in the process to understand the thought process of the designers in terms of the expected performance of the part, the ability of the part to connect to or interface with other parts (s), and other requirements such as the reliability of the part, quality, packaging, handling, shipping, and schedules. All these requirements are collectively referred to as ‘specifications’.

The Direct Material Sourcing process starts with a design or a specification for an item/part. When the Design Engineers & Product Engineers arrive at a design for the part, they share the design along with the specifications with the rest of the stakeholders using a document called Request for Purchase (RFP). Some companies call this a purchase request, purchase requisition, or sourcing request. The request is made on every new item (part).

Depending on the situation, the requests are made on an individual item level or a shortlist of items, or on an exhaustive list of all the items/ parts that make up the product. The structured list of parts that make up the product including the relationship between assemblies, sub-assemblies, and components, is called an engineering Bill of Materials (BOM or eBOM). Successful companies manage these requests through well-defined processes so none of the items/ parts are missed when working on 100s or 1000s of them in parallel. This entire process of coordinating between design, understanding and managing the requests, and working with the suppliers in converting these designs into parts (development) is usually referred to as New Product Development or NPD. The person from the sourcing department that oversees this process is referred to as a Sourcing Program Manager and is a critical part of the success of the product.

Make’ & ‘Buy’

With the BOM (parts list) now available, representatives from engineering, procurement, sourcing, manufacturing, production, and other departments meet to review the details of the parts and the specifications. During these discussions, such teams make a critical decision on whether to make those parts inside their factory or to request vendors/ suppliers to make them. When they decide to make those internally, the industry refers to such parts as ‘make’ parts. And where the decision is made to procure from the suppliers, they are referred to as ‘buy’ parts (A group of buy items that are fully designed and manufactured as small products by the suppliers is called Original Equipment or OE). And companies have different ways to denote these decisions inside their IT/ computer systems (ERP). Some parts may be produced within their factory as well as procured from the suppliers (‘make and buy’) for strategic reasons.

If the decision is to procure (buy) from suppliers, the RFPs are created and assigned to the appropriate buyers. The buyers ensure completeness of the information and reach out to the suppliers/vendors requesting them to submit quotations for the parts, in other words, referred to as Request for Quotation (RFQ). Depending on the criticality of the parts and the impact on spending and business operations, companies implement controls in these processes to enable the right level of management oversight concerning the nature of purchase and completeness of information for the suppliers to act on or to ensure engagement with the right suppliers. The right supplier for the right part is decided by procurement management in companies as part of the sourcing strategy. Developing the sourcing strategy in alignment with the company’s short-term and long-term goals is one of the primary roles of a Procurement Manager or Procurement Director. Other tactical requirements may include current challenges with suppliers, new parts under development, and total business volume/value with suppliers. Part of the strategy is also grouping parts into ‘categories’ or ‘commodities’ by criteria such as raw materials (plastic, rubber, chemical, iron, etc.) or manufacturing technologies (casting, forging, injection molding, etc.). Most sourcing organizations are set up as teams of specific commodities or categories.

Once the suppliers have submitted their quotations, the buyers review the quotations and place the detailed break-up of the supplier quotes side-by-side on spreadsheets to compare the quotes for the best cost of the part. Before this, companies make multiple estimates for the cost of the part. The buyers are usually experts in specific categories of parts with knowledge of the sources of raw materials, raw material/ commodity trends, and manufacturing processes for such parts. Because of this, they also create their estimates when reviewing the suppliers’ quotes. Larger companies also have dedicated cost engineering functions (Product Cost Engineers/ Value Analysts) that estimate these costs. In this way, the buyers and the buyer organization ensure they source the parts at the best cost possible. When selecting the suppliers for making these parts, apart from the cost of the part, the buyers also consider so many other aspects like the history of supplier performance, the financial strength of the suppliers, and capital investments made by the suppliers and specifically for the part, the distance between the point of manufacture to the point of requirement, etc. The buyers then release purchase orders (POs) to the selected suppliers.

This event of sending RFQs to multiple suppliers for an item/part is called a ‘Sourcing Event’ and the quotes are termed as ‘bids’ in some cases. A sourcing event is closed when a supplier(s) is selected for the part. Speaking of bids, in some cases, the companies procure items on a reverse auction basis where the part cost is published and the participants in the reverse auction can see the lowest price submitted (without the details of the supplier that quoted the price) and can quote a lower cost. This allows the buyer organization to obtain the best cost option in the sourcing event.

True to the iterative nature of the process in ‘Time to Market’, the sourcing and procurement team repeats this process of gathering quotations from suppliers and finalizing one or more, and releasing POs every time a new part is released or a newer design (version/ revision) of an existing part is released by the engineers. And the direct material cost of a product reaches the best value at the end of this process.

Different types of Purchase Orders

Depending on the situation, the type of purchase order may be different. There are 4 main types of purchase orders (PO):

1. Standard PO

2. Spot PO

3. Blanket Agreement

4. Blanket Releases.

There are also variations of standard POs like sample POs and there are also purchase contracts and supplier agreements.

Standard PO: is the most common type of purchase order that is released at the end of a supplier selection process for a part. There have been quotes from a few suppliers, and the buyers have negotiated and settled the final price for the part. The purchase order contains information like the supplier and buyer organization details, the place from which the part is shipped, the delivery address, billing address, the unit cost of the part, lead time for delivery of the part, quality requirements, and other terms and conditions including the payment time (payment terms) after the delivery of the part, etc. The standard POs have limited validity in terms of supply period and quantity. Sometimes they may be amended depending on the situation. Also, the POs are released after due approvals; different companies have different levels of approvals for the POs based on the purchasing value, type of purchase, etc.

Spot PO: is a slight variation of the standard PO in that the PO is released as a one-time purchase order on items without any RFQ process. Other terms in the PO are mostly the same as a standard PO. It is just like the name indicates… issuing a purchase on the spot to complete a transaction. When companies use a proper procurement system (procurement software), the need for spot POs reduces drastically. Most companies have a limit on the transaction values through the spot POs.

Blanket Agreement: (Blanket Purchase Agreement or Blanket Purchase Order) is a much broader agreement that is released at the end of a production sourcing, allowing the buyers and the suppliers to lock in the terms of purchase like cost, lead time, cost-saving over time, etc. for a long period of time. The duration of the blanket agreement varies between a few months to a few years. The advantage of a blanket agreement is that the company and the supplier can focus on the operational requirements instead of sourcing the same part over and over for highly repetitive purchases. While the blanket agreement locks in the purchasing terms and the duration of the agreement, it does not specify the quantity and exact requirement times. Blanket agreements actually require POs that follow the blanket agreements. These POs are sometimes called blanket releases. Some companies also colloquially refer to the blanket agreements as Open POs. Blanket agreements require updates every time the terms of purchase happen. One particularly frequent need to update the blanket agreements is the change in the raw material commodity rates that are used in making the parts. Based on the economic cycle, they either go up or down and as a result, the price of the parts also go up or down.

Blanket Release: is a purchase order that is released on top of an existing blanket agreement. It references the terms of purchase in the blanket agreement and also captures the quantity required and time of delivery. For most practical purposes, the blanket releases are similar to the standard POs. When processing supplier payments (vendor payments), the supplier raises invoices against each delivery, and payments are made against each invoice.

Apart from the fact that a PO is a final contract capturing all terms of the transaction, the POs are continuously modified depending on the item changes/revisions, quantities, prices, taxes, changes in ship-from and ship-to addresses, and simply to correct manual errors. Where there is a lack of a proper system, the sourcing and procurement staff spend a lot of time on such administrative tasks (very important nevertheless). That is where the best-of-breed procurement platforms understand the benefits of purchase order collaboration in real-time and help in handling these changes easily.

2.2 Parts Tracking

As engineers work together with other stakeholders to iterate and arrive at the final design during the New Product Development (NPD) or the Time-to-Market, the responsibility and effort do not just stop when the part is sourced (PO released) from the suppliers.

![]() The success of the new product program/project also depends on how the teams continuously keep an eye on and efficiently manage the steps involved after PO release right from making the parts at the supplier (which doesn’t necessarily mean standing with the suppliers’ engineers on their factory floor every time; even though when it comes to signing-off with the supplier for a long term contract, the buyers or supplier quality engineers (SQE) from the buyer organization or any of their contracted partners may have to do just that), to packaging and shipping from the supplier side, mode of transportation – land/ ocean/ air (logistics), to finally receiving the parts at the factory or warehouse and accepting the parts by the quality department and the engineers who designed the parts in the first place. All of this is to ensure the parts arrive promptly and at the right level of quality meeting all the requirements so that they can build the final product at the intended time and quality.

The success of the new product program/project also depends on how the teams continuously keep an eye on and efficiently manage the steps involved after PO release right from making the parts at the supplier (which doesn’t necessarily mean standing with the suppliers’ engineers on their factory floor every time; even though when it comes to signing-off with the supplier for a long term contract, the buyers or supplier quality engineers (SQE) from the buyer organization or any of their contracted partners may have to do just that), to packaging and shipping from the supplier side, mode of transportation – land/ ocean/ air (logistics), to finally receiving the parts at the factory or warehouse and accepting the parts by the quality department and the engineers who designed the parts in the first place. All of this is to ensure the parts arrive promptly and at the right level of quality meeting all the requirements so that they can build the final product at the intended time and quality.

Supply Chain Management (SCM)

This entire stream of activity after the selection and placement of the orders is handled by what most companies call the ‘Supply Chain’ department. Over time, the term Supply Chain Management has evolved into the umbrella term to include everything from building the sourcing strategy, supplier selection, and contract release (Procurement) to tracking to receipt of the materials in the warehouse. Supply chain management also includes the forecasting of risks in bringing the materials in the short term and long term, mitigation strategies, and contingency management in case of failures. Another critical area of focus of SCM is the forecasting of demand from the market and plan for the production and plan for the supplier readiness to meet the market requirements. For this discussion on Direct Material Sourcing and Procurement, let’s say, this may have taken the attention of management and information technology away from the process of sourcing and procurement. More on this later.

This entire stream of activity after the selection and placement of the orders is handled by what most companies call the ‘Supply Chain’ department. Over time, the term Supply Chain Management has evolved into the umbrella term to include everything from building the sourcing strategy, supplier selection, and contract release (Procurement) to tracking to receipt of the materials in the warehouse. Supply chain management also includes the forecasting of risks in bringing the materials in the short term and long term, mitigation strategies, and contingency management in case of failures. Another critical area of focus of SCM is the forecasting of demand from the market and plan for the production and plan for the supplier readiness to meet the market requirements. For this discussion on Direct Material Sourcing and Procurement, let’s say, this may have taken the attention of management and information technology away from the process of sourcing and procurement. More on this later.

2.3 Production Sourcing

To close the loop, the material is received from the supplier at the warehouse and then moved to a place within the factory where they are put together to create the (new) product. The feedback and the design changes then drive fresh changes – iteration of design-build-test-redesign. After a few cycles, the product and the parts that make up the product start maturing. At the end of which, the sourcing team completes a critical step called the Production Sourcing.

The overall sourcing process has been explained in detail above; except that in the case of production sourcing, the buyers look for suppliers that can support in providing the part throughout the production phase of the product – Time in Market.

Finalizing the suppliers with demonstrated quality and reliability for the longer term will also require approval of the specific tools and processes employed by the suppliers, along with various levels of checking of the parts. This concludes with approval of the supplier, tools, processes, and the part, and finally, a contract between the company (the buying organization) and the supplier for continued supply of the part.

Different products and industries have different requirements when it comes to approval criteria. For example, in pharmaceutical and medical devices, the approvals require several criteria set forth by the US FDA (United States Food and Drug Administration) or any other equivalent bodies around the world. In the case of Automotive, commercial and industrial equipment, a detailed ‘Production Part Approval Process’ or ‘PPAP’ is followed. PPAP requires at least 18 different documents to be checked before approving and signing off on the supplier and the part for the longer contract. Completion of the production part approval process is a very critical part of the Procurement Lifecycle for Direct Materials

PPAP – Production Part Approval Process

Apart from the fact that there are at least 18 levels of documentation and approval for every part, the application of these requires a high level of judgment backed by years of industry experience is critical to ensure timely closure of the sourcing process for these parts. Like always, things are never black and white or rather Approve or Reject; there is a wide spectrum of deviations in-between. For example, a fairly large part, let’s say a machine frame may have a few hundred points on to be measured and chances are some of the measurements are slightly off from their specifications. While in some cases a deviation of a few millimeters may not be a big deal, in some cases, even a fraction of a millimeter may not be allowed, depending on the application of the part. The decisions on deviations are taken at different levels and where it matters, the deviations are allowed only after reviews by all the stakeholders in the process (designers of the part, experts in quality, manufacturing, and production engineers involved in the making of the part, etc.). Why are there deviations? Answers to this question may take us on a whole different tangent; for now, let’s say, we don’t live in a perfect world and sometimes seemingly unrecognizable changes in a complex interaction like in the case of a manufacturing process can add up to become significant.

Without going into too much detail on PPAP, like the example we mentioned on the dimensions of a machine frame, there are other factors to be checked like the tools and processes used, the training and competency of the people using those at the suppliers’ place, the cleanliness, and safety of the space, the repeatability of all of these, consistency in delivering the parts within the specifications every time and the measure of consistency, etc are all reviewed before the part is approved for production. They also work with the suppliers to create plans for regular quality checks after the production part approval. In some cases, there may be requirements for repeating the complete production part approval periodically.

The group of engineers involved in this process on behalf of the buyers is called Supplier Quality Engineers (SQE). The group of engineers involved in this process on behalf of the buyers is called Supplier Quality Engineers (SQE).

The terms of the final contract at the end of the production sourcing may include several items such as:

-

- Contract Duration

- Cost of the part

- Targets and plans to continuously reduce costs (Direct Material Cost Reduction)

- Minimum Order Quantities per each order (MOQ)

- Plans for regular Quality Checks

- Total Quantity and/or Value of orders under the contract

One of the most common forms of contract is the Blanket Purchase Agreement containing all such information.

At this stage, the sourcing of the part is considered complete and the life cycle (& the ownership of the parts) rolls into the second phase of the Procurement Life-Cycle, that is the ‘Time-in-Production’; the useful life (revenue generation phase) of the product.

2.4 Supplier Payments

At every stage of the process, as the companies receive the materials (items/ parts), they are expected to pay the suppliers (some initial samples of the parts may be submitted at free-of-cost to the buyer, as part of the supplier qualification criteria). The payment to the suppliers is based on the quantities received against the quantity ordered by the buyer, and the number of items accepted by the quality department in the buyer organization. Depending on the terms of the purchase order for the batch of parts requested during the development phases, the payments are made, including or excluding the parts rejected by quality.

With this, we conclude part 1 of this guide. Hope it provided insights into how the procurement organization, particularly sourcing and supplier quality engineering, plays a vital role along with the product engineers in launching a successful product. Neither part 1 nor part 2 of this guide addresses anything related to software or solutions to help companies in managing the process. One may search for source-to-contract software or source-to-contract solution to identify software that may be relevant for their business. In part 2, we’ll discuss the procurement activities carried out during the production of the product. (Follow Zumen Inc on LinkedIn to know when part 2 will be published and receive notifications on more direct material procurement-related articles.)