FIFA World Cup: The Journey of the Event's Centerpiece

Business | December 02, 2022 | By

Football is an exhilarating sport. It is fast-paced and also boasts legions of fans, approximately 4 billion in number. That’s a touch more than half of the earth’s population. And the FIFA World Cup is the pinnacle of the sport’s events. In fact, the first-ever FIFA World Cup ended on a high because of an interesting tale.

A tale of 2 halves

The term, “a tale of two halves” gained much prominence in the world of football after the final whistle of the inaugural FIFA World Cup in 1930. The tournament used two balls – the Tiento and the T-Model belonging to the two finalists, Argentina and Uruguay respectively. Both of them wanted their balls to be used in the final showdown. A snowballing conundrum over a ball! FIFA decided to end this impasse by fielding Argentina’s Tiento in the 1st half and Uruguay’s T-Model in the second half. The reason why this turned out to be a controversy is because of the surprising results. When Tiento was used, Argentina was leading 2-1 in the 1st half. And with T-model in the 2nd half, Uruguay took the lead and the cup home with a final score of 4-2. Hence the phrase “a tale of two halves”.

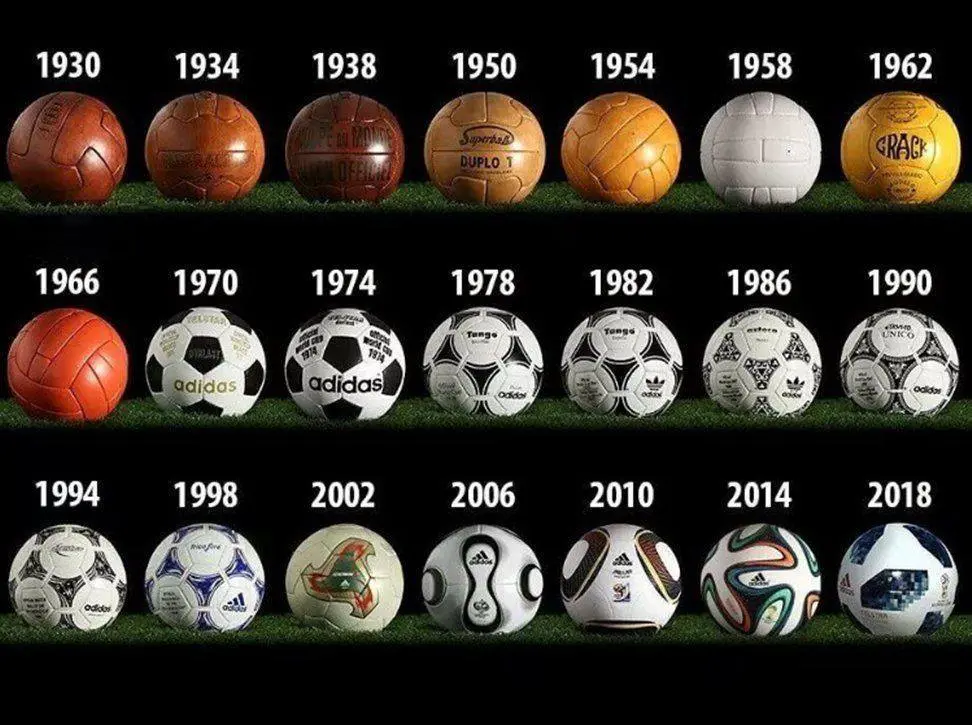

After that World Cup, nothing could capture the jubilance of the tournament, as the official match ball does. It is one of the most talked about topics, before, during, and after the tournament. Stories revolve around the world about its making, the technologies used, and most importantly, its performance during matches. And football has also evolved in tandem with the game.

Evolution of football

The journey of modern football as we see it today started with the work of Charles Goodyear’s invention of vulcanized rubber in the 1800s. (The earliest known football is said to have been made by the Chinese in 250 B.C. using an animal bladder.) This made the bladder- The bladder is one of the key components of a football. It affects the football in multiple ways, including air pressure, bounce, flight, weight, and shape – inflatable and improves the ball’s bounce too. But, the outer layer of the balls was made of leather. The problem is that leather stretches and the ball loses its shape after some time. Also leather can absorb water, making it heavy and difficult to play with.

All of this led to the invention of footballs with a synthetic outer layer in the 1960s with 32 panels -12 regular pentagons, and 20 regular hexagons. The balls were able to retain their shape better, stretch less, and absorb less water than leather balls.

The next era of football

After the synthetic outer came thermally bonded footballs with the first one kicked off at the 2004 European Championship. Since then, there have been many iterations of the ball. Additionally, carcasses were also added to the ball. Which is a layer between the panel and the bladder. This improves the consistency of the ball during impact.

Also, the panel designs radically changed. The 2010 FIFA World Cup ball, Jabulani, by Adidas, featured the fewest panels. 8 in number. And, the balls also featured a surface texture to enhance their aerodynamic performance. But, all of these enhancements did not stop Jabulani from becoming one of the worst FIFA World Cup balls ever. The balls faced a huge backlash for being lightweight and with unpredictable movements that sent them into Row Z.

After the FIFA World Cup debacle, the next FIFA edition balls – Brazuca, and Telstar 18 – were received well by players. The 2022 FIFA World Cup football, Al Rihla, comes with a radical design change. The ball is designed to reduce air resistance and also comes with a CRT-Core technology that increases the ball’s speed when in the air, maximum retention of shape, and rebound accuracy. And the Speedshell technology comes with a 20-piece panel, flight stability, and controlled swerve thanks to surface debossing, and macro-microtextures.

Smart Ball

Apart from the materials and the ball design, there’s smart tech too. After several testing, iterations, and development, the Goal-line Technology (GLT) was first implemented in the 2012 FIFA Club World Cup in Japan and all the other major leagues before it featured in the 2014 FIFA World Cup.

In the 2022 FIFA World Cup, the Al Rihla ball comes with motion sensors fitted inside. The Inertial Motion Unit (IMU) inside the ball will be able to report precise location data on the ball 500 times per second. This helps officials make more precise calls as to the position of the ball, or who to award the goal in close situations. In the ongoing tournament, the match between Uruguay and Portugal spurred a debate as to who scored the first Portugal goal. Adidas and FIFA awarded the first goal to Portugal captain Bruno Fernandes, and not Ronaldo, citing no external force acting on the ball as he crossed it. Brilliant, isn’t it?

How is it made?

Approximately 40 million footballs are manufactured each year. Each football measures about 8.65 inches in diameter. Arrange all the footballs in a single file and they will cover approx. 4.5 times the circumference of the earth.

A football is the culmination of the efforts of more than 100,000 people who work tirelessly in more than 6000 factories. And Sialkot city in Pakistan, the official manufacturer of FIFA footballs since 1982, is home to 70% of football manufacturing. The football manufacturing industry there is almost a 100-years old. Around 60,000 people work in this industry, which is approximately 8% of the city’s population. And approximately, 3000 balls made in Pakistan will be used for the FIFA World Cup 2022. There’s more. According to an estimate, 8 million replicas of the Al Rihla ball will be sold around the world.

The process of manufacturing a football starts with sourcing the right raw materials. The ball comprises a variety of rubber, polyester, latex, cotton, and other materials.

-

-

- Synthetic leather which makes up the outer layer of the ball comes from plastic, which comes from crude oil.

- The rubber bladder inside the balls is from plant extracts.

- The Poly-cotton cloth inner lining is from cotton plants.

- And the glue or latex adhesive comes from animals, fish, bones, etc.

-

For the 2022 FIFA World Cup, the Al Rihla ball is built with the environment in mind. And to make the fastest ball in the air ever, Adidas is said to have started design and development the moment France lifted the 2018 FIFA World Cup. With its radical design inspired by Qatar’s national flag, arts, and culture, the Al Rihla is the first ball ever to be made with water-based inks and glues. They are known as water-based because they are PVC-free and are devoid of CFCs, lead, heavy metals, and other volatile solvents.

This is not all. Since most of the balls are from Pakistan, the stakeholders have to plan the logistics in such a way that they travel the shortest, safest route (keeping in mind trade embargoes and the like). As the world moves towards a sustainable future, finding eco-friendly travel modes is imperative. If a football is shipped from Sialkot to Toronto (for the 2026 FIFA World Cup) by plane, the GHG emissions will be around 1.78 tonnes of CO2e, for example.

The Journey Ahead

Developing a product that will be the centerpiece of the tournament is not easy. And with sustainability, supplier diversity, and the like in the mix, the road ahead is filled with challenges. Next time you tune in to watch a match or are at the stadium, take a moment to appreciate the phenomenal effort taken to make things happen. From designing the ball to ensuring it is there at the stadium or in your hands when needed, while also keeping in mind the sustainability factors.

We at Zumen, understand that your direct material procurement process is as complex as manufacturing a football or even more. Moving forward, we as pioneers in the Direct Material Source to Pay space would like to join hands with you on the journey. Get in touch with us today by dropping a mail to [email protected] or schedule a free demo.