Scope 3 Emissions: Risks, Opportunities, and Role of Procurement

Business | August 25, 2022 | By

Earlier, sustainability was just a topic in boardroom meetings, but now, it is not so. It is becoming a pressing issue in organizations. And enterprises worldwide are calling for greenhouse gas (GHG) emission reductions like never before.

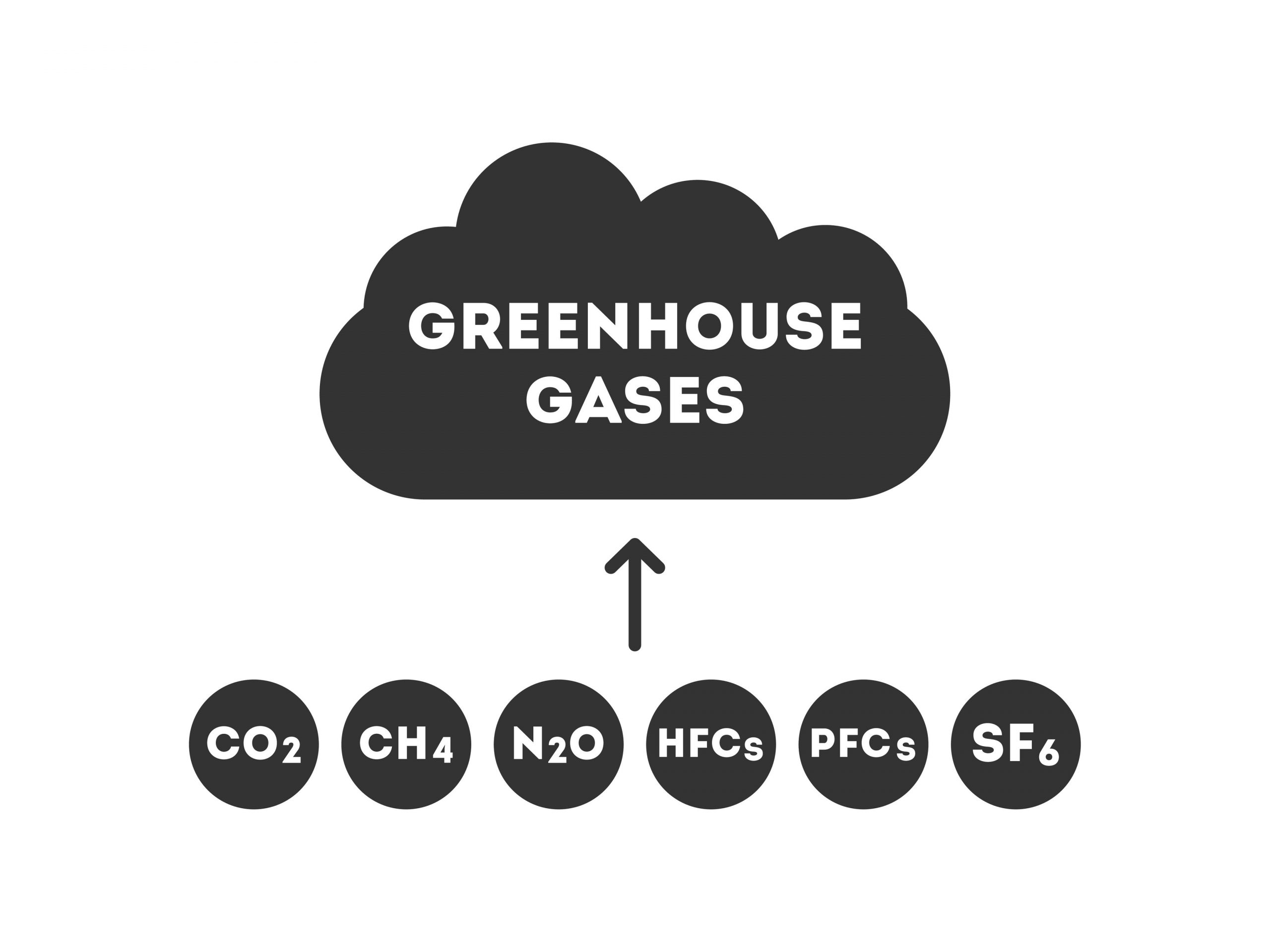

Gases that trap heat in the atmosphere are called greenhouse gases. The major constituents of greenhouse gases are

Gases that trap heat in the atmosphere are called greenhouse gases. The major constituents of greenhouse gases are

-

-

- Carbon Dioxide (CO2)

- Methane (CH4)

- Nitrous oxide (N2O)

- Hydrofluorocarbons (HFCs)

- Perfluorocarbons (PFCs) and

- Sulphur Hexafluoride (SF6)

-

The climate impact of an organization extends much beyond the scope of its own operations. In the case of product manufacturing companies, there is a lot of potential for emissions as they procure large quantities of goods and services from their suppliers. And according to the Environmental Protection Agency, U.S manufacturing accounts for about 23% of direct carbon emissions. The emissions come from upstream and downstream activities. Be it raw materials, capital goods, business and employee travel, leased assets, etc. The emissions released from these processes and activities are known as upstream emissions. And apart from the upstream emissions, the downstream emissions are emissions from the sale and use of the products, end-of-life treatment of products, investments, franchises, etc.

As per the Greenhouse Gas (GHG) Protocol, emissions are of three types: Scope 1, scope 2, and scope 3. Tackling and controlling scope 1 and scope 2 emissions is a big challenge in itself, financially and technically. Tackling scope 3 emissions presents an additional layer of complexity for organizations.

Scopes 1,2,3 Emission

Scopes 1, 2, and 3 are different carbon emissions from a company’s value chain.

The term first appeared in 2001 in the Greenhouse Gas (GHG) Protocol. It is the most widely used greenhouse gas accounting standard.

-

- Scope 1 emissions – These emissions come directly from the company-owned and controlled sources. For example, company transportation, company facilities, and running the boilers

- Scope 2 emissions – In other words, these emissions are indirect. They are emissions from the purchased electricity to provide energy or electricity that a company consumes for cooling, heating buildings, and other purposes.

- Scope 3 emissions – These emissions come from external sources, such as suppliers or end users.

While scope 1 and scope 2 emissions are generally straightforward to measure and are clearly defined by the GHG protocol, measuring scope 3 emissions is complex. They make up a significant portion of GHG emissions and encompass the complete upstream and downstream emissions.

Risks associated with Scope 3 emission

-

-

- Increased emissions means an increase in energy usage. So suppliers might pass on the cost to consumers. Also, high emission output is the result of operational inefficiency. Hence, this might lead to a reduction in supply reliability.

- With consumers increasingly conscious about the products they purchase, it is clear that they will only go for products whose GHG emissions are relatively low. So, companies with relatively high GHG emissions lose their share of business to those with lower GHG emissions, thus directly affecting their bottom line.

- Not only losing out on their share of the business, but enterprises also face litigation charges or an entity in their value chain.

- Also, there is backlash from consumers, stakeholders, and negative media coverage about the enterprise if its GHG management practices are not complying to the standard.

-

Benefits of controlling scope 3 emissions

-

-

- A reduction in scope 3 emissions leads to a reduction in costs and an increase in operational efficiency.

- With a comprehensive approach to managing GHG emissions, companies move towards developing sustainable business and supply chain practices, and also, there is innovation in the product design.

- When working towards controlling scope 3 emissions enterprises will realize improved stakeholder relationships. And this is achieved through proactively disclosing and demonstrating environmental stewardship, enhancing employee morale, demonstrating fiduciary responsibility, building trust in the community, and improving customer and supplier relationships.

- Enterprises can differentiate themselves from others in an increasingly environmental-conscious marketplace.

-

What can Procurement do?

We have seen the negative impact of scope 3 emissions on the enterprise. And so the onus now lies on procurement to ensure there are reduced scope 3 emissions in their enterprises’ value chain. As per GHG protocol, “Developing a scope 3 inventory strengthens company’s understanding of their value chain GHG emissions as a step towards effectively managing emissions-related risks and opportunities and reducing value chain GHG emissions.” And procurement is one of the key teams in an organization capable of tackling and controlling scope 3 emissions and has the greatest chance to reduce GHG emissions. With a strategic supplier relationship, enterprise-wide visibility into spend data, and critical decision-making power like early involvement in the design and development process and providing inputs based on past data, commodity details, etc. procurement can reduce the scope 3 emissions for good.

Forging Partnerships

Procurement teams should partner with all the suppliers, customers, and other companies in the value chain. With effective partnerships, procurement can gather GHG emissions data from the upstream side and engage with customers to provide information on product usage and disposal.

On one side, this aids in effective supplier relationship management. For example, a company may engage with its critical suppliers and obtain emissions information on the goods and services it purchases from them, as well as build a strategic relationship with the suppliers.

When engaging with downstream stakeholders like retailers, marketers, or advertisers, companies can convey pieces of information such as efficient ways to use a product, less energy-intensive products, or encourage recycling. Knowing where the risks lie helps to engage with stakeholders in a meaningful way to reduce their value chain emissions.

Increasing Transparency

Transparency in the process is not something new for procurement and is a must-have for their daily operations. They need to have transparency in the process, data, and management. Procurement teams should work with tools that provide seamless and comprehensive information connecting both PLM and ERP so that there is a single source of data. With data now available, procurement can utilize the spending data along with the supplier emissions report and find the hotspots in the value chain.

Buyers can work with those suppliers (hotspot areas) in the value chain and take proactive measures. For example, changing the packaging material to recyclable and sustainable materials or eliminating charger bricks in the sale of smartphones.

Savings Increase and Cost Reduction

Savings Increase and Cost Reduction

Finally, comes cost management. With relevant data available, buyers can make informed decisions and try to reduce costs. In this way, they can avoid energy and emissions costs in the future, thereby increasing savings in the bottom line.

Procurement’s Time to Lead

Procurement teams have a lot of responsibility riding on their shoulders. It is time they lead the march towards eliminating scope 3 emissions. And one of the ways they can do that is by removing the bottlenecks at the ground level. Data availability and transparency on the complete source-to-pay process would be a good start!

And that’s our mission at Zumen. To make data available when and how you need it. Schedule a free demo or contact [email protected].

Savings Increase and Cost Reduction

Savings Increase and Cost Reduction